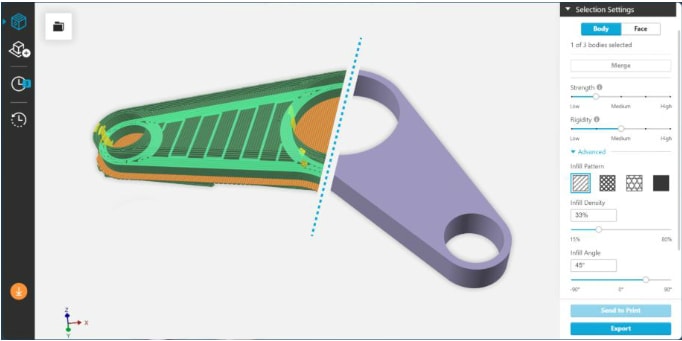

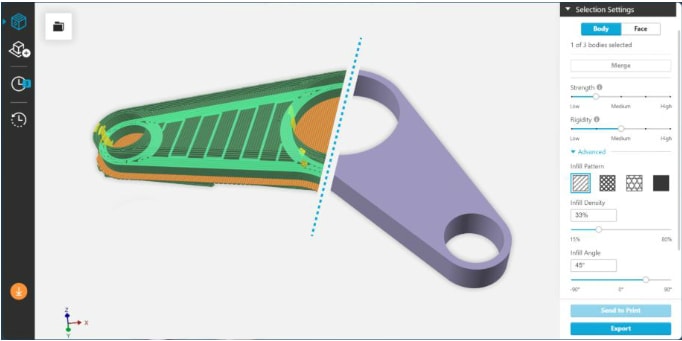

Easily customize individual feature characteristics to optimize build results.

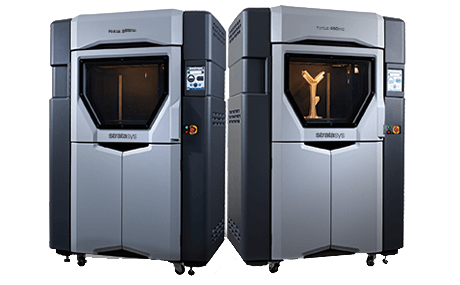

Get the speed and design freedom of advanced additive manufacturing in a 3D printer designed for production. The Fortus 450mc offers a generously sized build chamber to build prototypes, end-use parts and tooling in a production environment.

The Fortus 450mc is designed for ease of use with an intuitive touchscreen interface for a smooth, efficient workflow. Available materials include engineering grade as well as high-performance thermoplastics.

For demanding applications, rely on the Fortus 450mc for high-performance materials such as FDM Nylon 12CF (carbon fiber), ULTEM™ resins, PEKK-based Antero materials and ST-130 soluble material for sacrificial composite tooling.

Complex, high-requirement parts production means you can embed hardware, circuitry, and other non-thermoplastic materials into your parts easily, with minimal downtime for changeover.

High-capacity material options on the 450mc increase your unattended build time up to two full weeks.

Advanced additive manufacturing is combined with the latest advances in FDM technology so you can expand your manufacturing business with speed, agility, and the freedom of your own designs.

Reduced operation and training time since Fortus systems require minimal training to operate and maintain, with a simple touchscreen interface and easy-to-replace build trays and loading options.

No special facility requirements means you can install the Fortus printing systems anywhere since they produce no noxious fumes, chemicals or waste.

Get a Quote

Fortus systems are based on Stratasys FDM technology, so you can build durable parts with production-grade and high-performance thermoplastics. The Fortus 380mc gives you the option of up to eight different materials* while the Fortus 450mc lets you build larger parts with the materials you’re familiar with as well as high-performance thermoplastics* — such as FDM Nylon 12CF (carbon fiber) and ULTEM™ resins — for specialized industries like medical, aerospace, research and defense. You can also produce custom tools, prototypes and low-volume parts with consistent static dissipative properties, chemical resistance, unprecedented strength and superior PEKK performance with Antero 840CN03.

*Standard and engineering thermoplastics: Both the Fortus 380mc and 450mc. High-performance thermoplastics and sacrificial tooling material: Fortus 450mc only.

Drill jig, printed with Nylon 12 Carbon Fiber

System Size and Weight

129.5 x 90.2 x 198.4 cm (51 x 35.5 x 78.1 in)

601 kg (1325 lbs) without crate; 680 kg (1500 lbs) with crate

Build Size

380mc: 355 x 305 x 305 mm (14 x 12 x 12 in)

450mc: 406 x 355 x 406 mm (16 x 14 x 16 in)

Layer Thickness

Accuracy

Parts are produced within an accuracy of ± .127 mm (± .005 in.) or ± .0015 mm/mm (± .0015 in/in), whichever is greater).

Z part accuracy includes an additional tolerance of -0.000/+slice height.

Note: Accuracy is geometry-dependent. Achievable accuracy specification derived from statistical data at 95% dimensional yield.

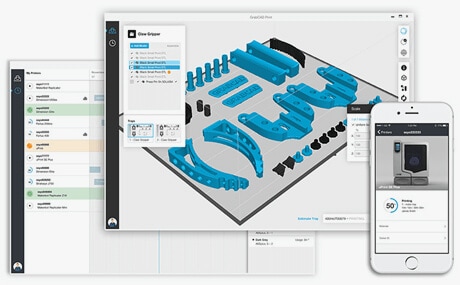

GrabCAD Print software makes 3D printing easy, accessible, and connected for Stratasys 3D Printers. Read and understand CAD files natively to help you simplify the preparation, scheduling, monitoring, and reporting of all your print jobs. GrabCAD Print offers an efficient workflow that streamlines job management in shared office and model shop environments using Stratasys 3D Printers. Adaptive Slice in GrabCAD Print is available.

Insight Software lets you print directly from your favorite CAD formats, eliminating the STL conversion and adjusting you used to do before printing. Optimize your productions with advanced control options that automatically adjust support structures and material extrusion paths, while giving you the ability to pause production in order to change materials or embed hardware or circuitry. Control Center lets you seamlessly share project information between users, creating a more streamlined, efficient workflow.

Microsoft Windows 10, Microsoft Windows 8.1 and Windows 8 (Pro and Enterprise), Microsoft Windows 7 (Pro, Enterprise and Ultimate), Microsoft Windows Vista (Business, Enterprise and Ultimate), Microsoft Windows Server 2008, Microsoft Windows Server 2003

Easily customize individual feature characteristics to optimize build results.

For more details, please contact your regional sales representative.

ULTEM™ is a registered trademark of SABIC or its affiliates.